PORTFOLIO OF: MARIELLE BACLAGAN SUDI SEMENTELA EDISON VOLANTE

Project Name

A description of the project and the works presented.

Wood Works – 2nd Quarter

Here, instead of working by function then form, we are taught to work from form them function. We will be starting with six pieces of wood to make a device that has the function determined after the design.

Design Task

We are to build a device made out of wood from only six pieces of wood, no more, no less. The focus of this project is to build something with an unusual design.

Design Brief

The design must have a purpose. The device must have an original design and has to show at least one reference to shape borrowing. It also has to follow the 6-piece wood rule. Design of device should be innovative.

Design Requirement

- Device should be useful in (if possible) everyday use.

- Shape borrowing should be a factor in the design process.

- Design should be original.

- Must shape-borrow from man-made structures.

Constraints & Considerations

| Constraints | Grade | Considerations | Grade |

| Should ONLY use 6 pieces of wood, no more, no less. | Final product could be any size. | ||

| Should NOT be made of softwood of plywood. | Product’s function depends on design | ||

| We have limited time. (one month and a half at most) | Other materials (metal, electricity, etc.) can be used as accents/part of the product as long as wood plays the main factor. | ||

| Wood to be used have maximum measurements. | Final product could be any shape. | ||

| Shape borrowing references should fit man-made structures. | Could use joints. |

Top Five

Constraints

- Should ONLY be made by 6 pieces of wood, no more, no less.

- Wood to be used per piece has maximum measurements.

- We have limited time on our hands.

- Should not be made of softwood or plywood.

- Shape borrowing references should fit man-made structures.

Considerations

- Product’s function depends on design.

- Other materials (metal, electricity, etc.) can be used as accents/part of the product as long as wood plays the main factor.

- We can use joints.

- Final product can be any size.

- Final product can be any shape.

Evaluation Criteria

- Is the device usable for most or is it unnecessary?

- Is it efficient?

- Is it too bulky?

- What other factors or accents are included in the product?

- What man-made structure is the product based on?

Investigation

Research

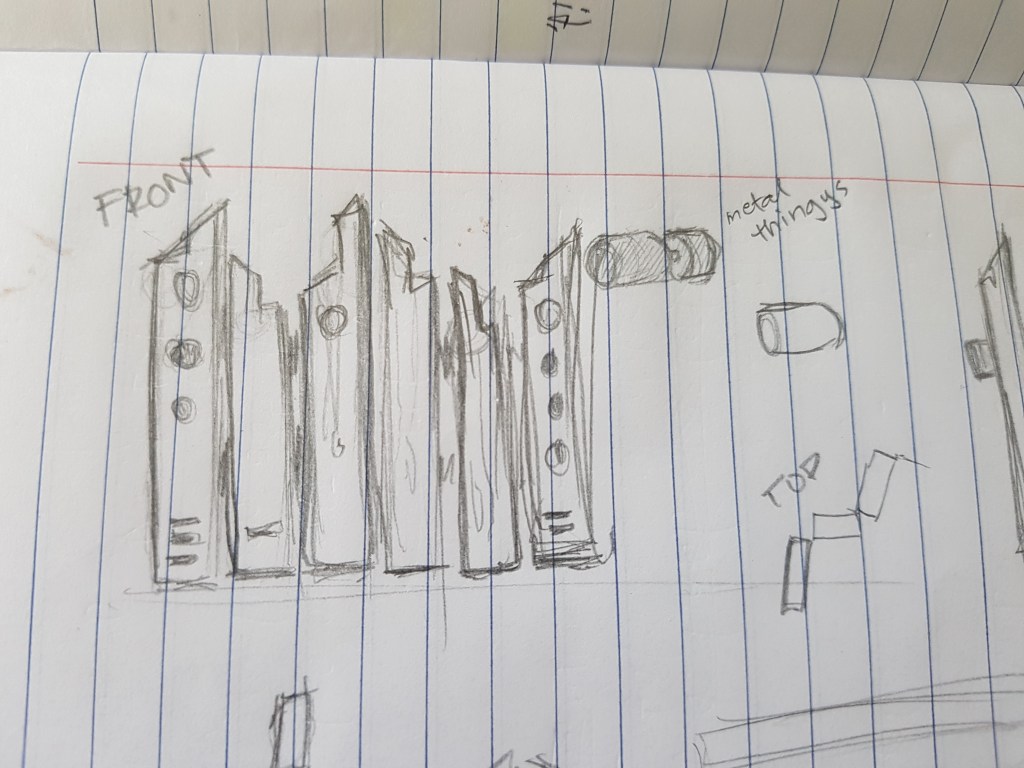

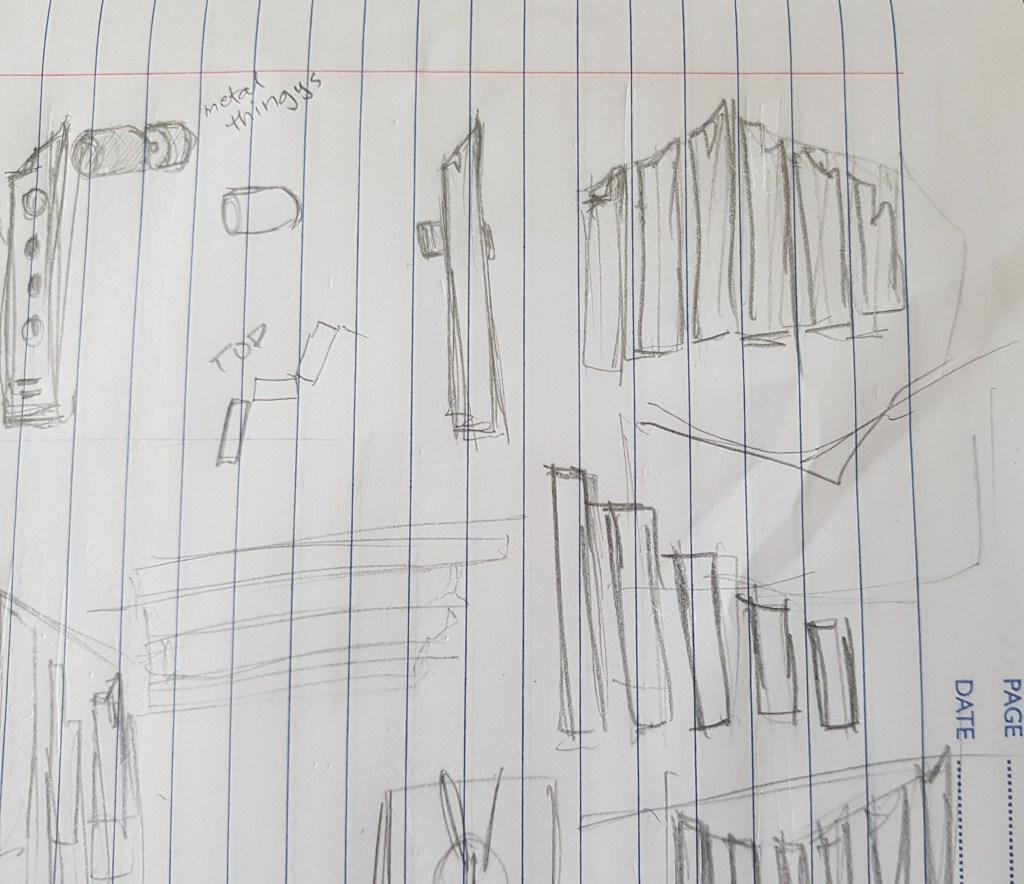

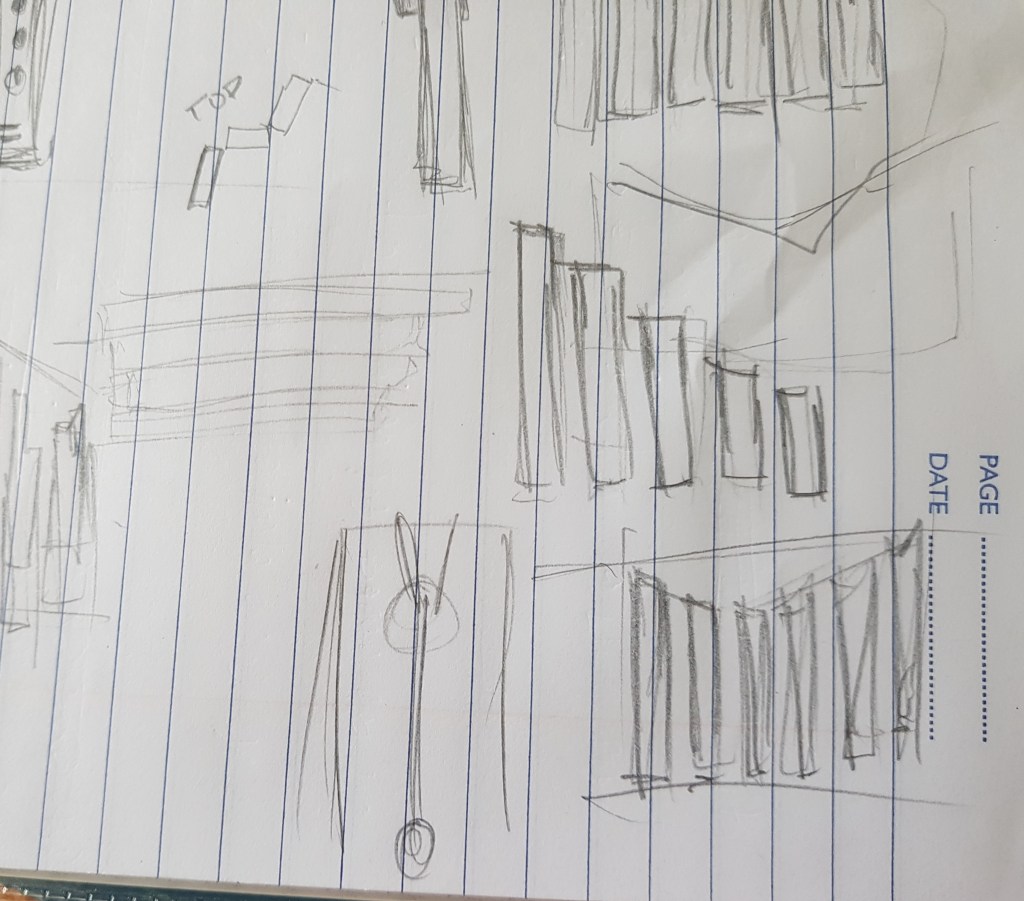

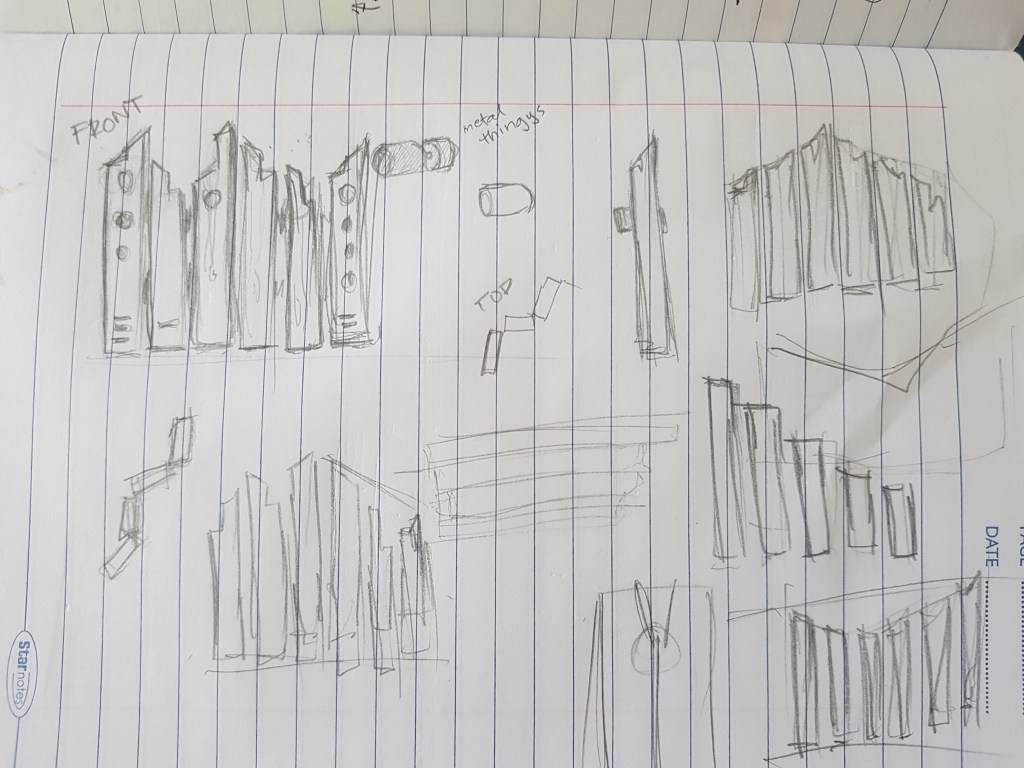

We started with a rough design resembling a divider (see pic below, fig. 1) . So, this design would surely have hinges. To add some variety, we wanted to add some things that would make it pop. We experimented with man-made structures and thought about buildings; more specifically the landscape you see when you look at a city of buildings (see pic below, fig. 2). It was uneven and it looked like just the characteristic we were searching for.

We decided to add holes in the device as accents, which could pose as high risks for we’re not sure if the tool we wish to use is too dangerous or not; or if the tool even exists at all. If it turns out that we can’t use it then we’ll have to use other accents to fill up the design for the product.

In the end we ended with a divider-like-accessory holder. all we had to do is attach hooks on the device and add accents to it. It would stand on it’s own and you could put it on your desk for a stylized accent for your room.

Production

Cutting List

| Part | Length | Width | Thickness |

| Pt 1 of Plank 1 | 25-27 cm | 4.5 cm | 1.5 cm |

| Pt 2 of Plank 1 | 27-29 cm | 4.5 cm | 1.5 cm |

| Pt 1 of Plank 2 | 28-27 cm | 4.5 cm | 1.5 cm |

| Pt 2 of Plank 2 | 26-25 cm | 4.5 cm | 1.5 cm |

| Pt 1 of Plank 3 | 24-22 cm | 4.5 cm | 1.5 cm |

| Pt 2 of Plank 3 | 20-21 cm | 4.5 cm | 1.5 cm |

| Pt 1 of Plank 4 | 21-19 cm | 4.5 cm | 1.5 cm |

| Pt 2 of Plank 4 | 25-23 cm | 4.5 cm | 1.5 cm |

| Pt 1 of Plank 5 | 23-25 cm | 4.5 cm | 1.5 cm |

| Pt 2 of Plank 5 | 26-27 cm | 4.5 cm | 1.5 cm |

| Pt 1 of Plank 6 | 30-28 cm | 4.5 cm | 1.5 cm |

| Pt 2 of Plank 6 | 28-26 cm | 4.5 cm | 1.5 cm |

Tools & Equipment

- Saw Drill

- Sandpaper

- Drill

- Screw

- Hinges (5 pairs)

- Screws

- Accents (Hooks & Designs)

- Wood Glue

Progress Chart

| Steps | W1 | W2 | W3 | W4 | W5 | W6 | W7 |

| 6. Drill hooks and metal accents | P | N | ✔ | ||||

| 5. Drill hinges | L | I | ✔ | ✔ | |||

| 4.Position hinges | A | N | ✔ | ✔ | |||

| 3. Glue planks together | N | G | ✔ | ✔ | |||

| 2. Cut wood | ✔ | ✔ | ✔ | ||||

| 1. Draw measurements | ✔ |

Production logbook: Journal entries

11/21/19

We are now starting with the production plan. We are still discussing our design. I suggested we make a foldable table, they agreed we could make something foldable. Now we’re here, drawing a guillotine. Ironically, it only requires six pieces of wood.

We’re not trying to commit murder, I swear. At least I’m not trying to commit murder, I don’t know about Myel. She suggested we make a crossbow.

Myel cries and decides to distract herself with the other things we need to encode.

Cogitation:

As of tomorrow, we might be able to think of something to get the design process going. As for today though, we had minimal progress but it’s still progress nonetheless.

11/22/19

We are still planning out some designs, making sure function follows form. We’re still sketching some shapes and figures.

We’re still making fun of the murder weapon concept (it was just a crossbow though, that would be cool ;-;) from yesterday, and getting ideas from that to incorporate in our final product.

As I look at the size of the wood pieces to work on, making sure to avoid squares and rectangles in the product will be hard, considering the wood is rather thin and long.

(I swear if we end up with a clock or something I’m going to go with my crossbow idea)

Cogitation:

Executing

11/26/19

We continued cutting the remaining planks using the jigsaw. Myel starts smoothening the cut planks.

Cogitation:

Since we’re now at our second step, hopefully we could cut these all so we could also add screws.

11/28/19

We cut the remaining the planks. Mark Edison and I didn’t hage much to do so we started smoothening the edges of the already cut planks.

Cogitation:

Now that there’s also someone doing the smoothening, work load might, hopefully, come by quicker.

11/29/19

We’re still cutting and smoothening the planks.

Cogitation:

I’m starting to like smoothening planks of wood.

12/3/19

We started going over and finalizing the design. We settled on the planks having random sizes.

Then we continued cutting. And smoothening.

Cogitation:

There is progress….I think.

12/5/19

I’ve noticed a traffic in using the tools, which is why Myel would have to before she even use the jigsaw. Which is also why I’ve been pretty bored.

Cogitation:

Cut planks coming my way is kind of slow. I think the said traffic is the cause of this.

12/6/19

We cut and smoothen planks as usual. Traffic really is causing at least two planks to be done. We also need to get around smoothing too.

Cogitation:

There’s much work to be done. I start getting around to smoothing to lessen work load.

12/10/19

While planks are being cut, and even as I’m writing this, I decided to use what I call soundproof headphones, ones that are used to block out noise while using the power tools.

Cogitation:

Like I’ve said, progress is progress. I believe we’re still on the stage of cutting the planks. Even if progress was slow, it’s still progress.

12/12/19

As usual: we cut and smoothen our planks. We talked about gluing the already cut and smooth planks together while Myel cuts the rest.

Cogitation:

If this does come true, then we’d be moving on to the next step, which is gluing the planks.

12/13/19

We glue the already smooth planks together. Mark Edison accidentally got glue on his hands.

Cogitation:

Right now, all we need to accomplish gluing all the planks and we’ll now add hinges. We’re a step in the right direction 😀

12/17/19

We cut and smoothen the remaining planks.

Cogitation:

I honestly don’t know if this is the last of it before moving on to the next step.

01/14/20

Our planks are now hinged and Myel and Mark Edison attached the hooks while I update this journal.

Cogitation:

Yay! We’re done or 99% done.

01/16/20

We drill more on the planks to add hooks.

Cogitation:

We’re almost done with step 6, adding hooks.

01/17/20

We smoothen the holes made on the planks, Myel continues to drill hinges. I’m done with the progress chart too:D

Cogitation:

We are doing much progress in my opinion.

Evaluation

As we come to an end, it’s safe to say that our product works well for what it was meant for. We, at least, think that it looks aesthetically pleasing, personally. It met the design briefs and the design was simple, but we got to incorporate ‘form over function’ in it. It agreed with the evaluation criteria.

There were problems throughout the process of building the artifact. For one, we weren’t able to make the holes that we initially planned, and it left a mark when we tried to drill a hole in it. We did try to cover it up with accents and it did look like it added charm to it. We were able to reference our initial inspirations to the product and it, personally, looked like it’s what made the design pop.

We could’ve improved on some bits, like add a small lampshade or plug-ins that wouldn’t make it look so plain, but that’s just our take on it. The small, circle mark is definitely one of the most unsatisfying touches of the product.

Overall we think the product was nicely done. It was fun to do and very educational. We’re very proud of the outcome.